Yesterday I spent the day in the bilge. Replaced the electric bilge pump with an automatic one, which barely fit. I love my Arima but whoever designed the bilge access deserves a kick in the butt. Installed a "backup plan" while I was at it. The hose on this manual pump can reach anywhere in the back of the dance floor and into the in-floor fish box and bilge access. Under normal circumstances it is on a quick release with the pickup in the splash well. I ride a little butt heavy so the theory is I can use it to get some water out of the splash well in a following sea.

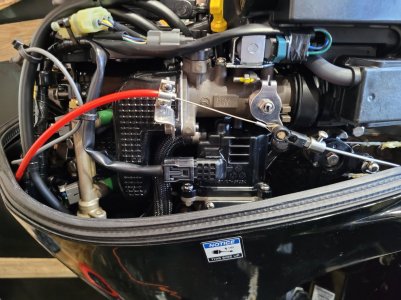

And today I sea trialed the kicker steering connection I made up this winter. Worked exactly as intended. It was pretty dead calm out there today though, we'll see how it does in sportier conditions.

And today I sea trialed the kicker steering connection I made up this winter. Worked exactly as intended. It was pretty dead calm out there today though, we'll see how it does in sportier conditions.