-Jim-

Member

Hi Gents,

Quick Question looking for answers:

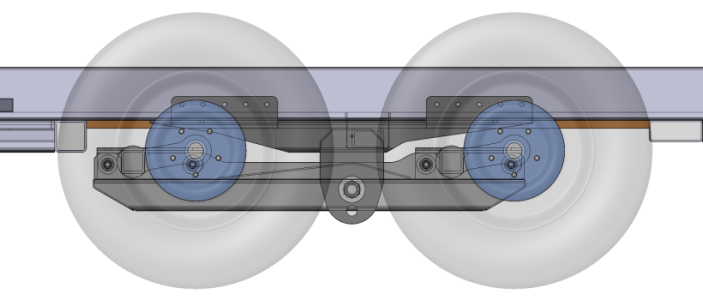

Any downside or benefit to Torsion Arm suspension over typical Leaf Springs?

I was recruited to help a Buddy look at a used Galvanized EZ Load Trailer to replace his painted (read RUSTY) one that came with his boat he bought used 3 or 4 years ago. I advised him when he bought the boat the paint wouldn't stand up to the salt water, but he got a deal.

Anyway, I advised him I have zero experience on a trailer with Torsion Arm suspension on a EZ Load Boat Trailer Model EZB 17-20 3100 (2800) => 22 foot trailer / 3100 pound capacity, but I'm certain some of the Gents here certainly will.

Please advise any pros or cons you know of. A timely response would be appreciated.

Thanks for the assist.

Quick Question looking for answers:

Any downside or benefit to Torsion Arm suspension over typical Leaf Springs?

I was recruited to help a Buddy look at a used Galvanized EZ Load Trailer to replace his painted (read RUSTY) one that came with his boat he bought used 3 or 4 years ago. I advised him when he bought the boat the paint wouldn't stand up to the salt water, but he got a deal.

Anyway, I advised him I have zero experience on a trailer with Torsion Arm suspension on a EZ Load Boat Trailer Model EZB 17-20 3100 (2800) => 22 foot trailer / 3100 pound capacity, but I'm certain some of the Gents here certainly will.

Please advise any pros or cons you know of. A timely response would be appreciated.

Thanks for the assist.