InterMechanico

Well-Known Member

@Sharphooks I think he means:

- Use a straight edge laying against the bottom of your hull aligned with each engine to measure the height of the underside of the anti-cavitation plate relative to the hull. Make sure your engines are trimmed to make the anti-cavitation plates parallel with the hull when you take your measurement. Take your measurement at the center point of the anti-cavitation plates.

He mentioned that the anti-cavitation plates should be higher than the hull by 1.5" for every foot of setback from the transom. He also mentioned that it would be alright to try raising the engine 1"/foot of setback to start, eg: raise them 3", by estimating the pod to be 36" long.

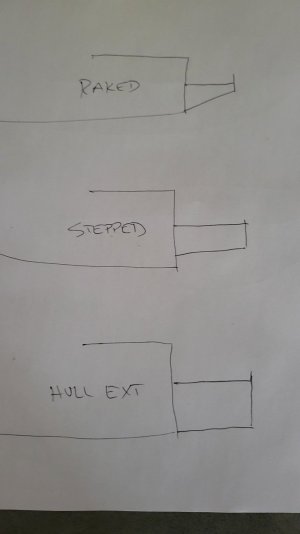

If your pod is Not raked upward and carries the profile of the hull backward to the mounting plate, then you would measure your setback from the bottom or the pod mounting plate.

If you pod is raked upward, then you would take the setback measurement from the bottom edge of the transom.

- Use a straight edge laying against the bottom of your hull aligned with each engine to measure the height of the underside of the anti-cavitation plate relative to the hull. Make sure your engines are trimmed to make the anti-cavitation plates parallel with the hull when you take your measurement. Take your measurement at the center point of the anti-cavitation plates.

He mentioned that the anti-cavitation plates should be higher than the hull by 1.5" for every foot of setback from the transom. He also mentioned that it would be alright to try raising the engine 1"/foot of setback to start, eg: raise them 3", by estimating the pod to be 36" long.

If your pod is Not raked upward and carries the profile of the hull backward to the mounting plate, then you would measure your setback from the bottom or the pod mounting plate.

If you pod is raked upward, then you would take the setback measurement from the bottom edge of the transom.

Last edited: