Hi,

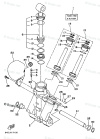

I have a Yamaha 150 outboard and it seems like there is some oil leaking from the tilt trim area. From what I can see it may be coming from the tilt trim motor but I am not certain on that. Does anyone have any suggestions on what this might be? The purple line in the picture is where I could see the oil running from but I can't see in behind there. That is the tilt trim motor on the left hand side.

Any thoughts on this would be much appreciated.

Rob

I have a Yamaha 150 outboard and it seems like there is some oil leaking from the tilt trim area. From what I can see it may be coming from the tilt trim motor but I am not certain on that. Does anyone have any suggestions on what this might be? The purple line in the picture is where I could see the oil running from but I can't see in behind there. That is the tilt trim motor on the left hand side.

Any thoughts on this would be much appreciated.

Rob