MiddlepointBight

Well-Known Member

Hi all,

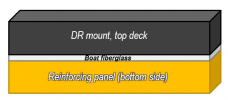

I'm re-mounting some hp scotty riggers (bailing on the 90 degree gunnel mounts that came with boat), and have two materials to chose from to reinforce the bolts/mount on underside of gunnel (standard 4 bolt mount).

I have an offcut of 3/4" ply, and in addition, an offcut of 1-1/4" transdeck. Trying to decide what to use, and don't have a ton of experience with transdeck, but it looks pretty bombproof!

thanks for any insights

I'm re-mounting some hp scotty riggers (bailing on the 90 degree gunnel mounts that came with boat), and have two materials to chose from to reinforce the bolts/mount on underside of gunnel (standard 4 bolt mount).

I have an offcut of 3/4" ply, and in addition, an offcut of 1-1/4" transdeck. Trying to decide what to use, and don't have a ton of experience with transdeck, but it looks pretty bombproof!

thanks for any insights